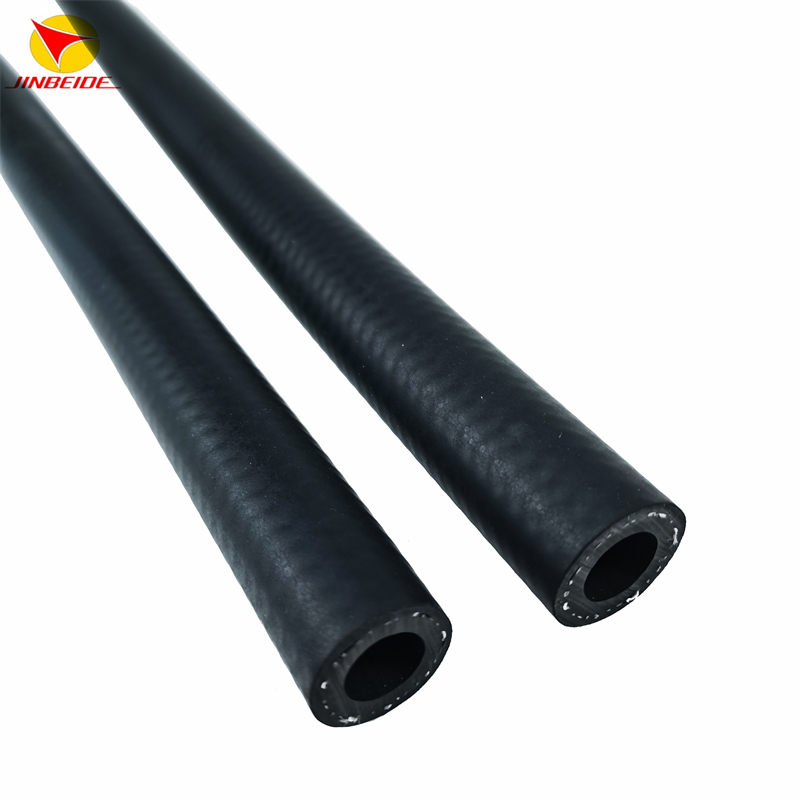

Fuel Injection Fuel Hose

| Productum: | Fuel Injection Fuel Hose |

| Item No.: | JBD-E017 |

| Magnitudo & Figura: | ID≥Φ2.5 mm; Lorem ut erat. |

| Materia: | FKM/ECO; FKM/YARN/ECO NBR+PVC NBR/YARN/NBR+PVC |

| Color: | nigreos |

| Applicationem | Usus ad Fuel Iniectio, Fuel Supple ratio in Automobiles, Trucks, Motorcycles.ATV, Horti Machinaria, Engines, Generatores et cetera |

| Standard | SAE, YDK, HES, EX-S, ASTM et sic porro |

| Shipping Portus | Xiamen |

| OEM/ODM | Accepit |

| sarcina | PE bag+Carton+Pallet |

| Pensio conditio | T/T, L/C, Unionis occidentalis |

| Factory | ISO/IATF16949 relatus |

| Technical Teams | 30+ Annorum experientia |

| Sample Leadtime | 7-15 diebus |

| Productio Leadtime | 20-30 diebus |

SPECIFICATION

| Test conditio et eventus | ||||||||||

| NO | Item | Test Condition | Basic valorem | Test Precium | Iudex | |||||

| 1 | Gaudete test | Test rupta pressura | ≥6.2MPa | 7MPa | OK | |||||

| 2 | Vacuum Collapse Test | 81KPa,15-60 seconds | OD Mutans Rate, Max:-20% | -6.5% | OK | |||||

| 3 | Col Flexibility | A) Ad 135℃×70Hrs etatis ad calorem siccum esse, post canus, ut -40℃×5Hrs ad moratus | Fixum in camera frigida per 180 gradus a centro ad diametrum 10 temporum Max OD caligarum | NON FRACTURA, NO rimas, NOCHEKS, BREAKS | OK | |||||

| rumpe pressura ≥0.69MPa | 0.81MPa | OK | ||||||||

| B) Ut in ASTM Oleum N. 3 pro 135℃×70H immergatur, tunc in -40℃×5Hrs habitudo est. | Fixum in camera frigida per 180 gradus a centro ad diametrum 10 temporum Max OD caligarum | NON FRACTURA, NO rimas, NOCHEKS, BREAKS | OK | |||||||

| rumpe pressure≥0.69MPa | 0.76MPa | OK | ||||||||

| 4 | Distrahentes fortitudo | Tegumen ≥8MPa Midium/Interna ≥5MPa | Exterior: 10MPa Midium:10MPa Interior: 9MPa | OK | ||||||

| Prolongatio | Tegumen ≥150% Medium/interior ≥125% | Exterior: CCLIX% Midium:296% Interior: 276% | OK | |||||||

| 5 | Arida calor Resistentia | Ater 150℃ * 7days esse senex, lente corrigas | Superficies sine crepuit et carbonization | Nulla elit et carbonization | OK | |||||

| 6 | ALUMENTUM REpugnantia | Ut in ALUMENTUM C RT * 48Hr | Interiorem iacuit rate of volumen mutatio ≤+10% | 7% | OK | |||||

| 7 | OLEUM RESISTENTIA | Ut baptizetur in ASTM oleum III # CL℃ * 7Hrs | Tegumen Mutare distrahentes vires ≤ + C% | 55% | OK | |||||

| 9 | OZONE REPENSATIO | PRO ASTM D MCXLIX, SPECIMEN LICEBIT REQUIESCET IN OZONE LIBER XXIII℃×24H, ET IN EPULTIS SPECIMEN IN TESTA CAMPIS CONTINENS OZONE AT 100MPA×40℃, POST 70Hrs EXPOSITIO. | NO CRACKS (Visum inspiciendum sub 7X MAGNIFICATIO) | Nulla Cracks | OK | |||||

| 10 | ADHESION | Longitudo 25.4mm | cortices vires ≥35.6N | 75N | OK | |||||

| 11 | kink REPREHENSIO | 300MM SPECIMEN LONGI, 23℃×2H, HOS FLECTO NATURALI CURVIO ET ALTERUM FINEM DILIGENTER IN ALTERAM FORAMEN INSERTO, donec ex altera parte eminet 63 mm. | Pila libere transire | Pila libere transire | OK | |||||

| 12 | Test cibus Ethanol | Baptizari in 85% ALUMENTUM D + 15% absolutum ethylum alcohol RT *70Hr | Interior Stratum: mutatio rate de distrahentes strengthMax -40%; | -20% | OK | |||||

| Interiorem Iacuit: Muta rate in elongationem:Max -40%; | -28% | OK | ||||||||

| Interiorem Stratum: Chang rate Volume: Max 0-15% | 7% | OK | ||||||||

| 13 | OXIDIZED fuel test | —Ce tria distrahenda (D471 C#) specimina in 200ml mixturam immersis constans 3600 mL ASTM Fuel "B" et 10 ml 90% t-butyl hydroperoxidis pro 40℃*14 diebus | Interior Stratum: mutatio rate de distrahentes strengthMax -30%; | -15% | OK | |||||

| Interiorem Stratum: Muta rate in elongationem:Max -20%; | -12% | OK | ||||||||

| 14 | Humilis Permeation test | ASTM FULE C, MODIS CONFORMATIO AD 9.1~9.2 et EPA Regul | ≤15g/m2/day | 10.2 | OK | |||||

OEM & ODM

High Quality Automotive / Motorcycle Fuel Supple System Fuel Iniectio Fuel Hose accipi potest OEM & OEM sicut per clientes delineatas , exempla aliaque specificationes late applicantur in effectibus automobile et motocycle ac machinae industriarum effectae, Fuel Hose,, High Temperature & High Pressure Fuel Hose, Fuel Iniectio (EFI) Fuel Hose, Air Intake Hose omnia in officina nostra fabricata sunt.Omnes hoses, quos fabricavimus, in laboratorio nostro submittuntur probationibus necessariis et occurrentibus vexillationibus SAE, YDK, HES, EX-S, ASTM et sic deinceps;

Materiae principales sunt FKM/ECO;FKM/ECO/YARN/ECO;ACM/YARN/ACM;NBR/YARN/CSM;NBR/YARN/NBR+PVC;NBR+PVC;NBR+CSM/CM;

NBR, NR, ECO, ECO/CSM.et sic porro.

APPLICANDIS

High Quality Automotive / Motorcycle Fuel Supple System Fuel Injection Fuel Hose late utere pro Fuel Injection System, Fuel Supple System in Automobiles, Trucks, Motorcycles, ATV, Horti Machinaria, Engines, Generators et reliqua.

Uniquie commoda nostra:

A: 30+ Years Experti Professional Technical Teams with strong R&D Center.

B: Potens capacitas cum 4 Factories Productio Base.

C: Qualitas stabilis et pretium auctoris – Nos integra societas coniungendo Purgamentum materias crudas exacutio & processus Mixer et Purgamentum producta fabricandi cum technicis professionalibus, necnon Purgamentum Raw Materials Wholesales.

D: Delivery time--20-30 dies ad massam productionis.

Ita, OEM/ODM gratum esse potest.

Pleraque nostra producta sunt nativus et fabricata sicut per clientes tractus et Requisita.

Ita, PPAP scriptor documenta fundamentalia sub libello nostro IATF16949 est.

T/T et L/C acceptus est.30% downpayment and balance before shipment by T/T.Vel C% irrevocabilis LC ad aspectum.

Praecipua nostra Purgamentum & materia plastica sunt NBR, SBR, NR, ACM, AEM, CSM, ECO, FKM, VMQ, EPDM, SILICONE, PVC,TPU, ect.

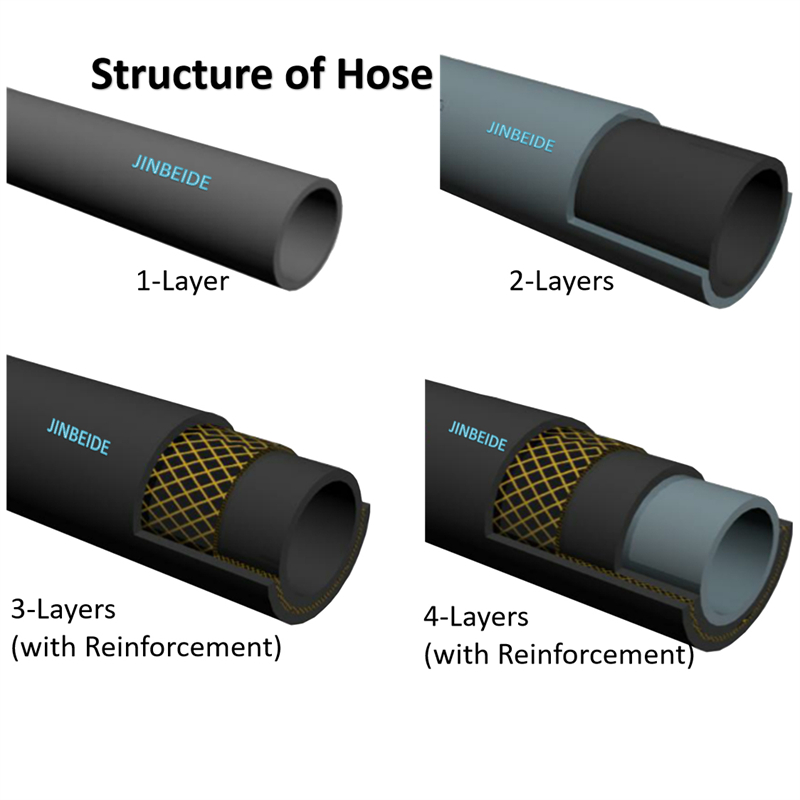

Structura Hose

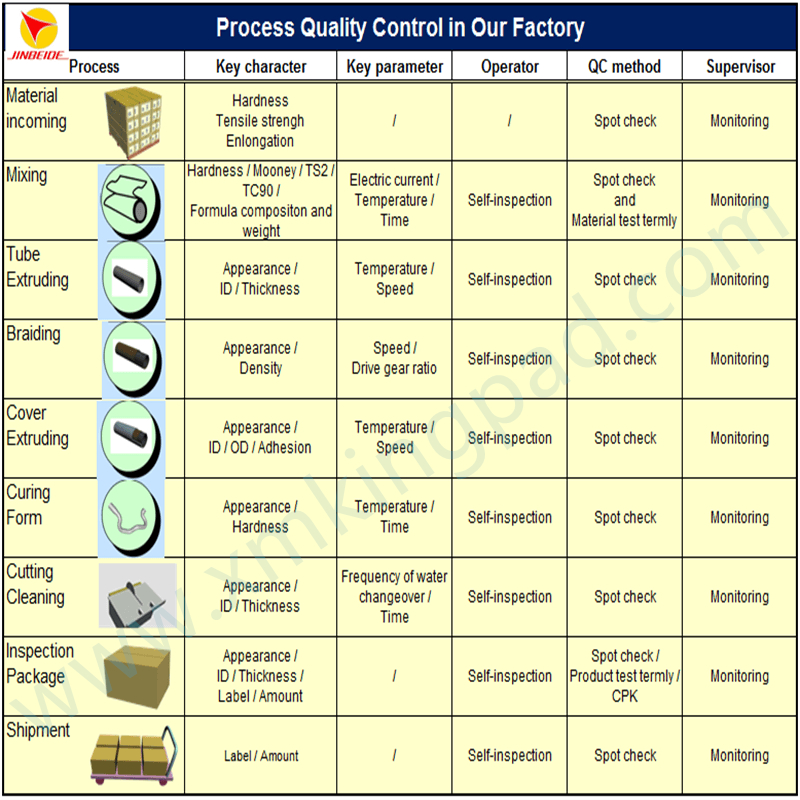

Processus Qualitatis Imperium

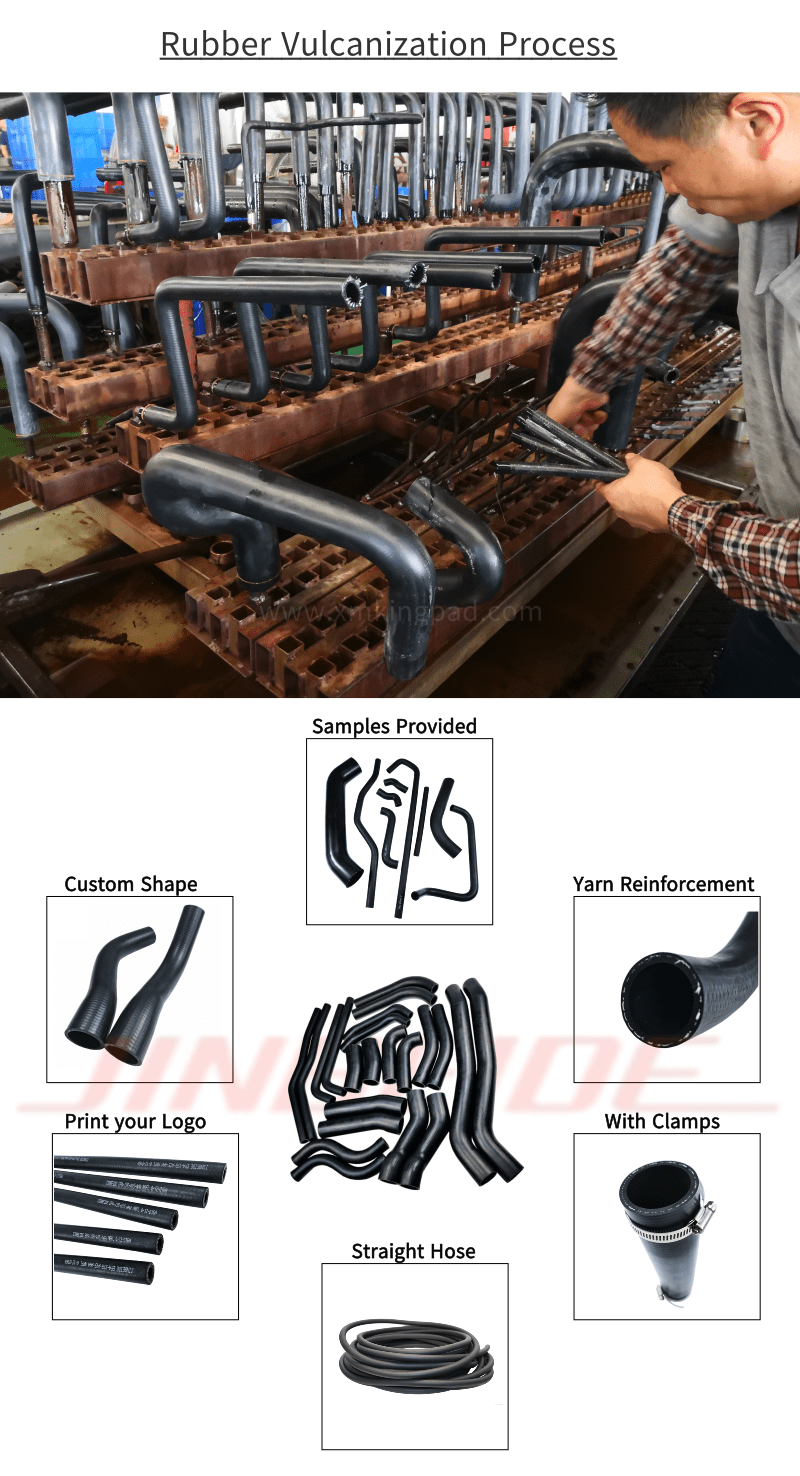

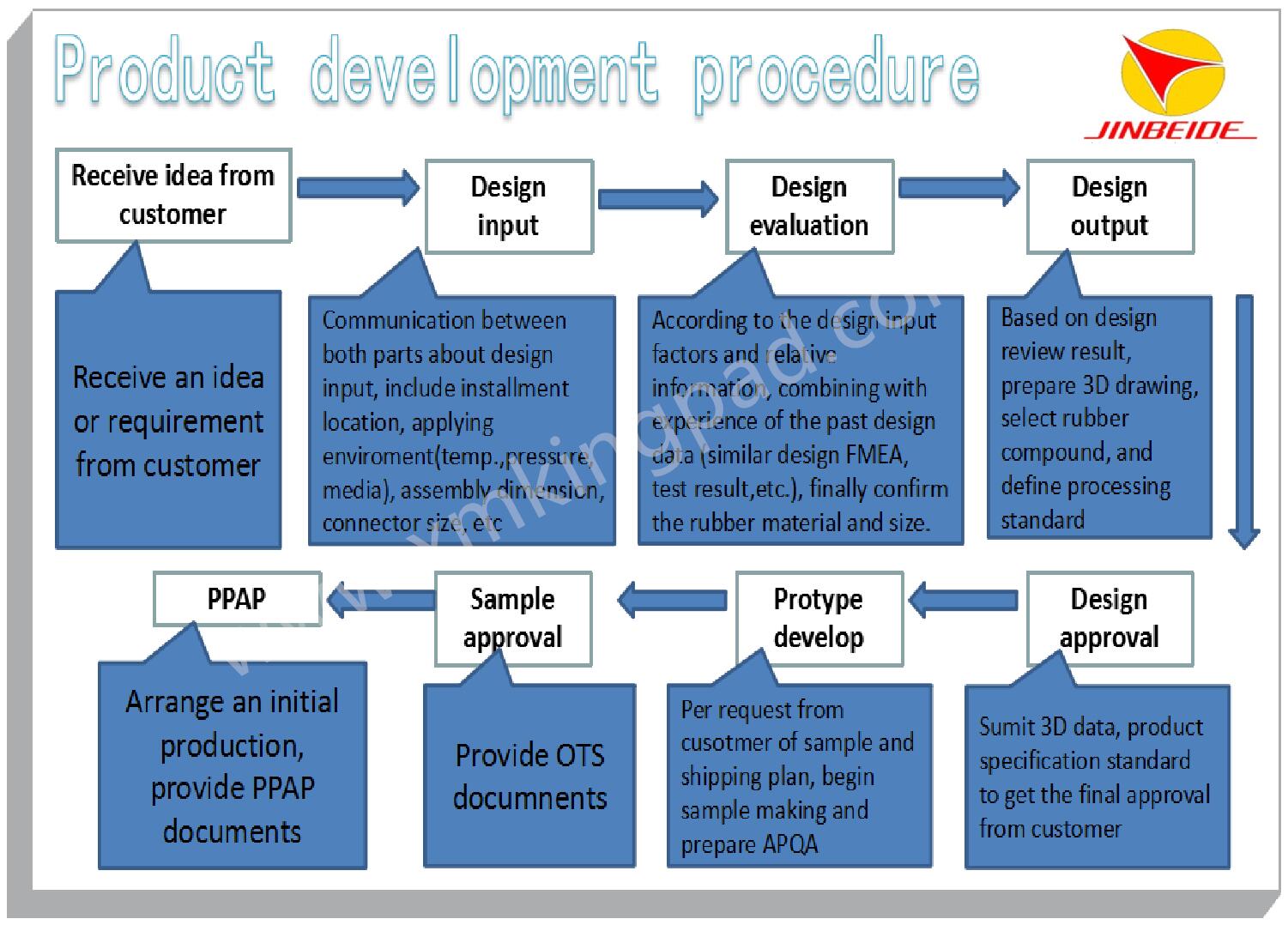

Processus Product Development

Products Collecta

Packaging & Shipping